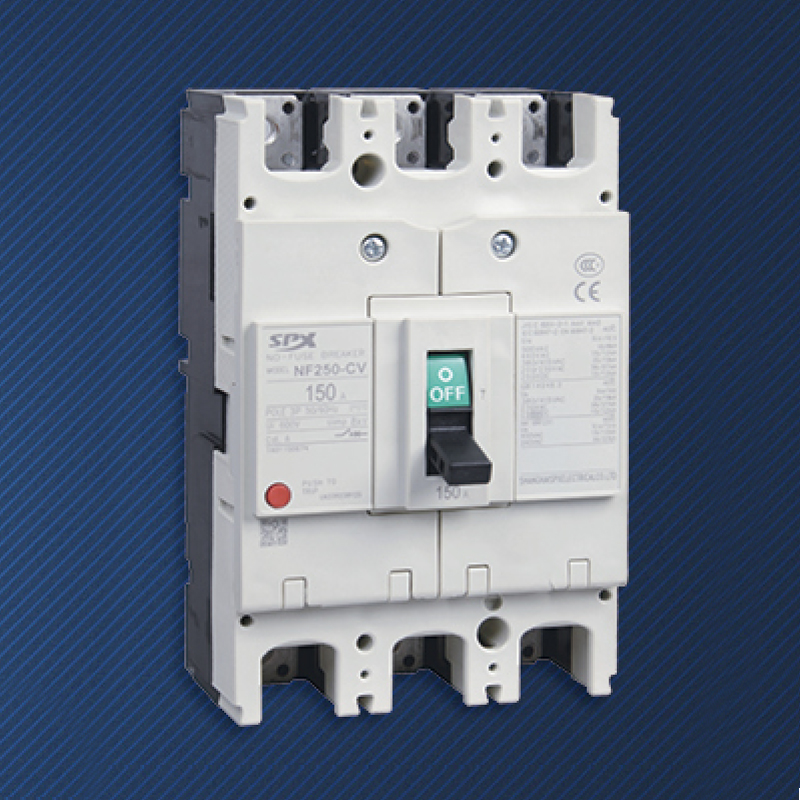

SM50-250 Thermal magnetic molded case circuit breaker

Product Details

Product Description

Thermal-magnetic molded case circuit breaker is an electrical protection device that combines thermal protection and magnetic protection functions, and is widely used in industrial and commercial power systems. Its main function is to protect the circuit from overload and short circuit faults.

How it works:

1.Thermal protection:

Use a thermal element (usually a bimetallic strip) to detect current overload. When the current exceeds the set value, the thermal element bends due to heat, eventually triggering the circuit breaker to trip and cut off the circuit.

2.Magnetic protection:

Short circuits are detected by electromagnetic components. When the current reaches a certain short-circuit current value, the electromagnetic component will quickly close and immediately cut off the circuit to prevent equipment damage and fire risks.

Advantages:

Dual Protection: With both thermal protection and magnetic protection, it can effectively deal with different types of electrical faults.

Quick response: In the event of a short circuit, it can quickly cut off the power supply to protect the safety of equipment and personnel.

Adjustability: Many thermal-magnetic molded case circuit breakers allow users to adjust the overload protection value according to actual needs, enhancing flexibility.

Durability: The plastic shell material has good insulation performance and corrosion resistance, suitable for various environmental conditions.

Easy to maintain: Reasonable structural design, easy to install and maintain, reducing the cost of use.

Thermal-magnetic molded case circuit breakers are important protective devices in modern power systems and can effectively improve the safety and reliability of electrical equipment. When selecting a thermal-magnetic molded case circuit breaker, it is necessary to configure it reasonably according to the specific circuit requirements, load type and working environment. Make sure that the selected circuit breaker complies with the relevant electrical standards and specifications to ensure the safe and stable operation of the system. During installation, follow the manufacturer’s instructions and electrical installation specifications to ensure correct wiring and commissioning of the circuit breaker to achieve the best protection effect.

The SPX SM50-250 Series Of Moulded Case Circuit Breaker MCCB Parameter

| Frame(A) | SM50-250(NF-CV) | ||||||

| Rated current In(A) | 100、125、140、150、160、175、200、225、250 | ||||||

| Rated voltage(V) | AC 400V | ||||||

| Rated insulation voltage(V) | AC 690V | ||||||

| Number of poles | 3 | 4 | |||||

| Limited breaking capacity | C | S | H | C | S | H | |

| Short circuit interrupting capacity(kA) AC400V |

18 | 30 | 50 | 18 | 30 | 50 | |

| Operate short circuit(kA) AC400V | 9 | 15 | 25 | 9 | 15 | 25 | |

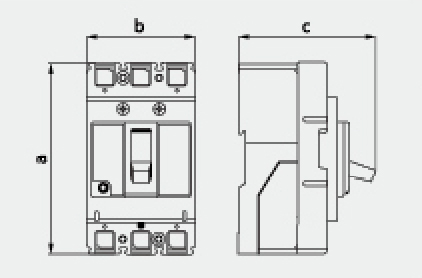

| Profile picture | |||||||

|

a | 165 | 165 | ||||

| b | 105 | 140 | |||||

| c | 90 | 90 | |||||

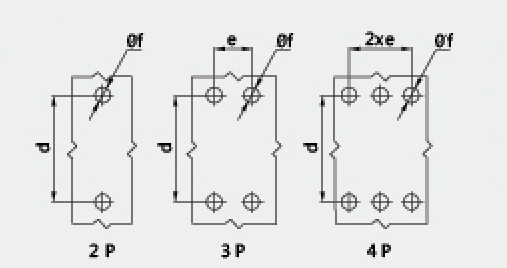

| Mounting picture | |||||||

|

d | 126 | 126 | ||||

| e | 35 | 35 | |||||

| f | 5 | 5 | |||||

| Machine life | 4000 | ||||||

| Electrical life | 2000 | ||||||

| Electrical-operation device(MD) | ● | ||||||

| Extemal rotary handle | ● | ||||||

| Automatic tripping device | Thermal-magnetic | ||||||

Online message