SS-N21 magnetic switch AC contactor

Product Details

Product Description

Magnetic switch AC contactor is an electrical switch used to control motors and other electrical equipment. It is widely used in industrial automation and power control systems. It uses electromagnetic principles to realize the on-off control of the circuit and can work safely and reliably under high current and high voltage conditions. The design of this contactor enables it to withstand higher loads and ensure stable performance in various working environments.

The structure of an AC contactor usually includes main contacts and auxiliary contacts. The main contacts are responsible for the main switching function of the circuit, while the auxiliary contacts are used to implement additional control functions, such as indicator lights, signal feedback, etc. This design enables the contactor to meet a variety of control requirements, provide flexible operating options, and adapt to different application scenarios.

AC contactors are also very adaptable and can work normally in harsh environments such as high temperature, high humidity, and dust. This makes them widely used in industrial production, building electrical, transportation and other fields, and they have become an indispensable and important part of modern electrical control systems.

Magnetic switch AC contactor meets the needs of modern industry and commerce for electrical control with its high efficiency, reliability and versatility. With the continuous advancement of technology, the performance and function of AC contactor are also constantly improving, providing a strong guarantee for the safe operation of various electrical equipment.

Magnetic switch AC contactor is an electrical switch used to control motors and other electrical equipment. It has many advantages, mainly including:

1.High reliability:

Magnetic switch contactors adopt electromagnetic principle, have high contact reliability, and can maintain stable performance under frequent operation.

2.Quick response:

Due to the characteristics of electromagnetic drive, the contactor can switch states quickly and is suitable for applications that require fast start and stop.

3.Remote Control:

Remote operation can be achieved through control circuits, facilitating centralized control in large equipment or complex systems.

4.Overload protection:

Many magnetic switch contactors can be used in conjunction with thermal relays to provide overload protection to prevent motor damage due to overload.

5.Versatility:

Magnetic switch contactors can be used with various accessories (such as auxiliary contacts, time delayers, etc.) to expand their functions and meet different control requirements.

6.Save Space:

Due to their compact design, magnetic switch contactors take up less space in the distribution cabinet, helping to improve the overall layout efficiency of the distribution system.

7.Durability:

Made of high quality materials, with good wear and corrosion resistance, suitable for use in various environmental conditions.

8.Security:

Safety is taken into consideration in the design, which can effectively prevent misoperation and electrical failure, and protect the safety of equipment and personnel.

SPX Household AC Modular Contactor Parameter

| Frame(A) | SS-N21 | ||||||||

| KW/HP(AC-3) Reted power(AC-3) IEC60947-4 | 220V | 5.5/7.5 | |||||||

| 380V | 11/15 | ||||||||

| Reted current(AC-3) GB14048.4 | 220V | 22 | |||||||

| 380V | 22 | ||||||||

| Reted heating current(A) | 32 | ||||||||

| Reted insutaled voltage(V) | 660 | ||||||||

| Auxicary contact AC-15 | Contact | Standard | 2NO+2NC | ||||||

| Reted current (A) | 220V | 1.6 | |||||||

| 380V | 0.95 | ||||||||

| Electric life | 100 | ||||||||

| Machanical life | 500 | ||||||||

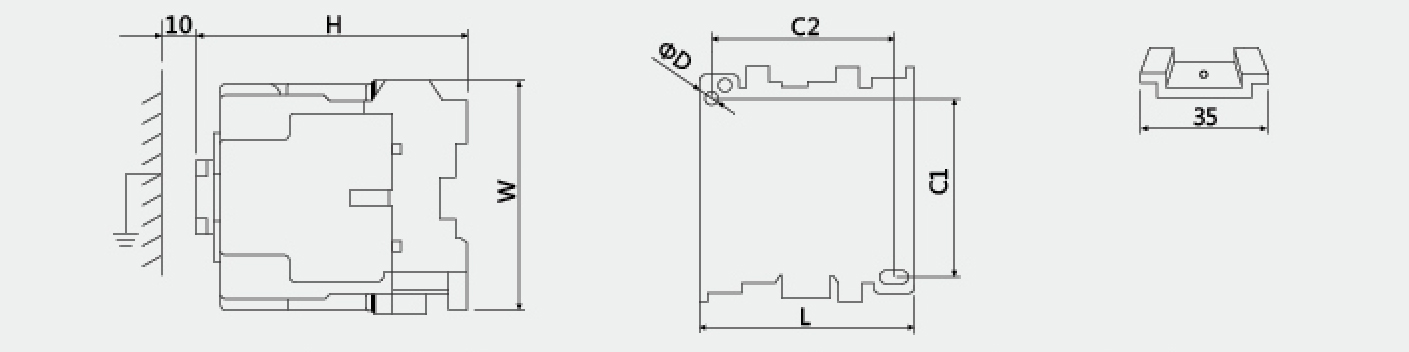

| Outline and installation dimension |  |

||||||||

| Type | L | W | H | C1 | C2 | ΦD | |||

| SS-N21 | 63 | 81 | 81 | 60 | 54 | 4.5 | |||

Online message