SS-N65 AC motor contactor with overload

Product Details

Product Description

In the field of electrical control systems, AC motor overload contactors are key components for protecting motors from potential dangers. Their main function is to prevent overload and short-circuit faults, ensuring the service life and reliability of electrical equipment. By understanding the various functions and advantages of AC motor overload contactors, operators can improve the safety and efficiency of the system.

One of the most important features of an AC motor overload contactor is its overload protection capability. When the current flowing through the motor exceeds a predetermined safety threshold, the overload contactor automatically disconnects the circuit. This action prevents the motor from overheating, which can cause serious safety hazards, including equipment damage or even fire. By providing this necessary protection, overload contactors play a vital role in maintaining the operating integrity of motors and related machinery.

In addition to overload protection, AC motor overload contactors also provide short circuit protection. When a short circuit occurs, the contactor can quickly cut off the power supply, thereby protecting the motor and other electrical components from potential damage. This fast response is critical to preventing catastrophic failures that can result in expensive repairs and extended downtime. The ability to mitigate such risks highlights the importance of incorporating overload contactors into electrical systems.

Another noteworthy feature of some AC motor overload contactors is the automatic restart function. Once the fault is corrected, these contactors can automatically restore the circuit and restart the motor without human intervention. This feature not only improves operational efficiency, but also minimizes the risk of human error during the restart process. As a result, businesses can maintain productivity while ensuring that their equipment is operating within safe parameters.

AC motor overload contactors are often equipped with indication features, such as indicator lights or alarm devices. These features allow operators to monitor the operating status of the motor in real time, which helps to detect potential problems early. By providing immediate feedback on the health of the system, overload contactors enable operators to take proactive measures, thereby reducing the possibility of unexpected failures and costly downtime.

SPX AC Contactor Switch Parameter

| Frame(A) | SS-N65 | ||||||||

| KW/HP(AC-3) Reted power(AC-3) IEC60947-4 | 220V | 18.5/25 | |||||||

| 380V | 30/40 | ||||||||

| Reted current(AC-3) GB14048.4 | 220V | 68 | |||||||

| 380V | 66 | ||||||||

| Reted heating current(A) | 100 | ||||||||

| Reted insutaled voltage(V) | 660 | ||||||||

| Auxicary contact AC-15 | Contact | Standard | 2NO+2NC | ||||||

| Reted current(A) | 220V | 1.6 | |||||||

| 380V | 0.95 | ||||||||

| Electric life | 60 | ||||||||

| Machanical life | 300 | ||||||||

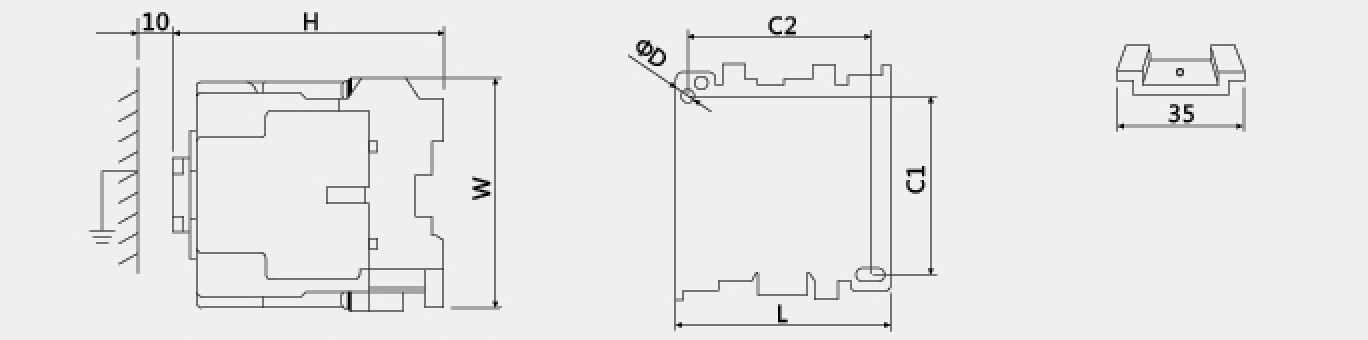

| Outline and installation dimension |  |

||||||||

| Type | L | W | H | C1 | C2 | ΦD | |||

| SS-N65 | 88 | 106 | 106 | 75 | 70 | 5 | |||

Online message